Customization

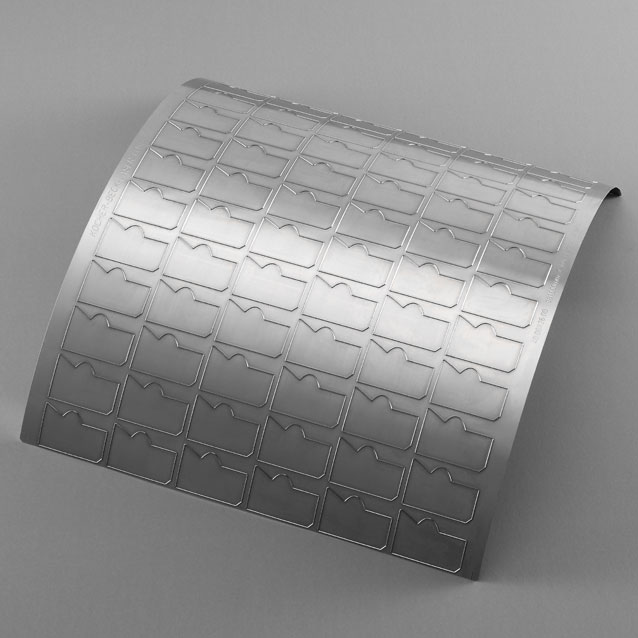

Differentiate yourself from the competition and customize your labels to meet your specific requirements. We provide the solutions, you make the impact. We offer a combination of rotary, thermal, flatbed, and digital die-cutting technologies for a variety of materials, including PVC. Our team is experienced in handling complex shapes and multilayered constructions. Our slitting process includes an inspection camera system to ensure that each roll is flawless.